Semi-synthetic success

A supplier machining cast iron compressor scrolls experiences significant benefits with Tech Cool® 35035NB semi-synthetic fluids

The Audit

Chemetall always begins with an audit. No issue can be corrected without fully understanding the situation.

- Chemetall conducted a line audit with a benchmark analysis coupled with a product compatibility test.

- To save additional cost of disposal, the 45,000 gallon central system processing the cast iron was charged up with Tech Cool 35035NB by going over the top of the incumbent coolant.

- The process/compatibility trial ran for 60 days to prove performance, supply, and support.

The Tech Cool 35035NB Payoff

- Reduced Coolant usage by $150,000

- Eliminated sump side biocides and additives

- Stable supply chain and improved forecasting

- Enhanced product stability

- Improved service and support with routine analysis

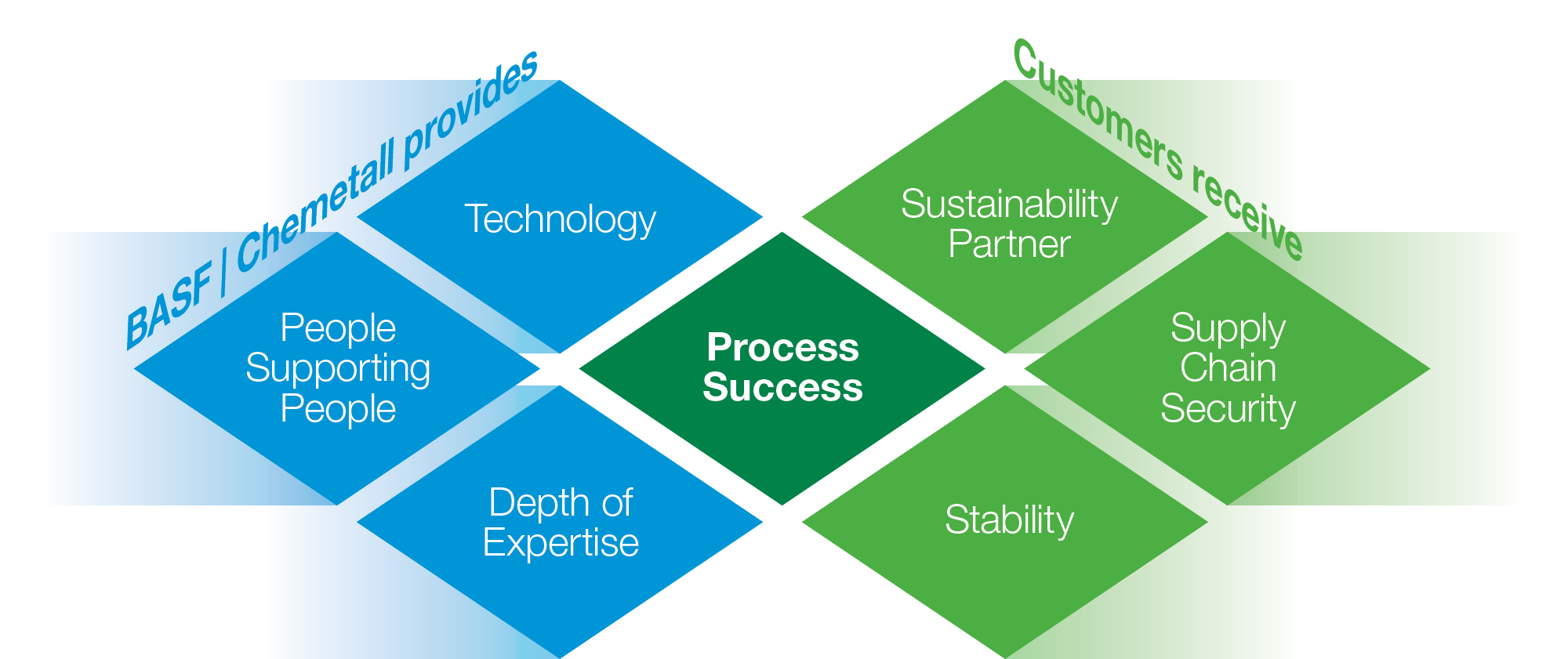

Building partnerships through support.

Post process goals

The customer goals were to improve supply chain stability, use a higher

quality, dependable product, and reduce or eliminate sump side additives

for biocides.

Tech Cool 35035NB was the answer.

Measurable results

- On time deliveries

- Reduced coolant usage

- Reduced and eliminated sump side additives

- Improved forecasting

Material improvement

The manufacturer has now also switched to Tech Cool 35035NB in the 60,000 gallon central system.

Both the 45,000 and 60,000 gallon central systems are now operating at peak efficiency.

We develop, manufacture, and supply best-in-class technologies, systems, and expertise.

Download a PDF of this case study click here.