Gardo® Filter — Media Filtration System

Precision filtration system for excellent iron removal in advanced pretreatment and acid neutralizing baths

Introducing the Gardo Filter — Media Filtration System

The Gardo Filter — Media Filtration System is the ultimate solution for advanced filtration needs. Engineered for industrial-grade performance, the Gardo Filter — Media Filtration System is specifically designed to efficiently remove iron from Chemetall's advanced pretreatment and acid pickle neutralizer process baths.

Gardo Filter System benefits:

- Skid mounted for easy placement

- Built-in fluid purge system

- Automatic backflush comes standard

- Durably designed with Industrial components

- Designed for easy maintenance & repair

Far more capable than all predecessors, this innovative media filtration system is what your process needs to succeed!

This robust filtration system features a durable stainless steel construction, including a direct-drive industrial pump capable of handling 1/8" solids without damaging the impeller. The stainless steel filter housing comes equipped with a strainer basket to capture larger contaminants, ensuring they don't interfere with the media filters' performance.

The Gardo Filter — Media Filtration System incorporates composite filter tanks with a two-part design, allowing for straightforward disassembly and maintenance if media solidification or component replacement is needed.

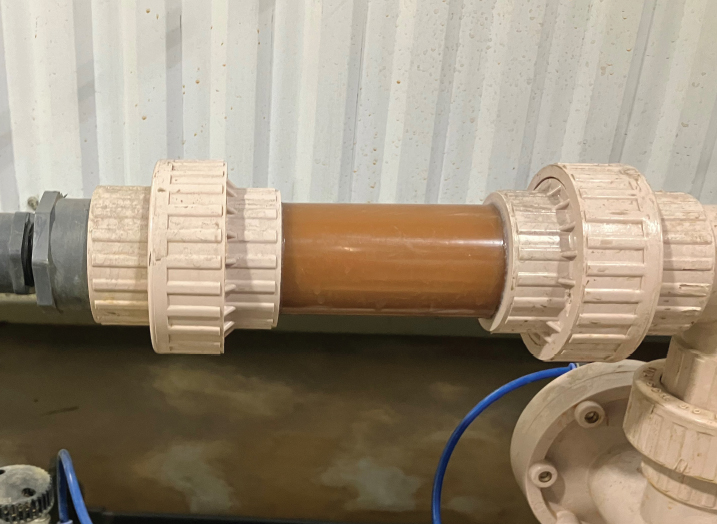

The system's PVC plastic piping, with union connections, facilitates easy assembly and disassembly. Safety is a priority with a built-in pressure switch that automatically shuts off the pump if filter pressure approaches the maximum limit.

The intuitive backflush controller is user-friendly, allowing for quick adjustments. Operators can set the backflush to trigger based on a timer, inlet/outlet pressure differential,

or manual activation. For reliable backflushing, the advanced backflush control system includes decoders and actuator valves, along with a master backflush backpressure valve, to optimize performance.

Unparalleled filtration performance

Before and After photos are from an actual installation on an advanced pretreatment process tank. Click and image to view larger.

Typical advanced pretreatment bath

without Gardo Filter

Bath samples taken before and 1-hour after

Gardo Filter filtration begins

Concentrated iron contamination discharging during backflush

The system delivers superior backflushing performance

- Balanced Flow and Distribution: Provides uniform flow across the media bed, promoting balanced and effective filtration.

- Full Vertical Backflush Flow: Ensures that all backflush water is directed vertically, effectively lifting and flushing the entire media bed.

- Complete Media Cleaning: The vertical flow pattern ensures thorough removal of iron from the media.

- Eliminates Channeling: Avoids uneven water distribution, eliminating the problem of wasted backflush water and ensuring optimal filter performance.

- Reduced Backflush Solution Consumption: Efficiently uses less backflush water, reducing overall process solution consumption.

Choose the Gardo Filter — Media Filtration System for unparalleled reliability and efficiency in your filtration processes.

Gardo Filter — Media Filtration System schematics

Click images below to view large.

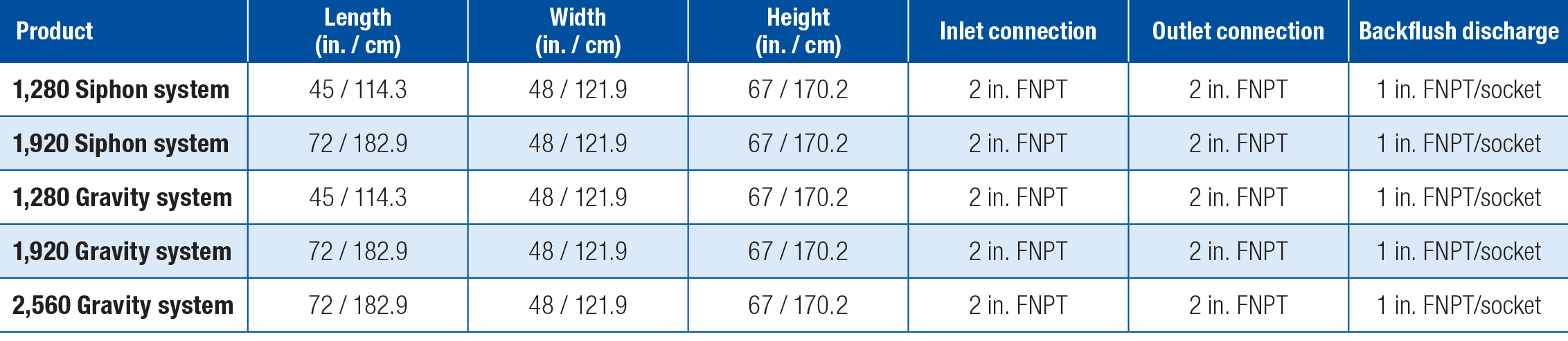

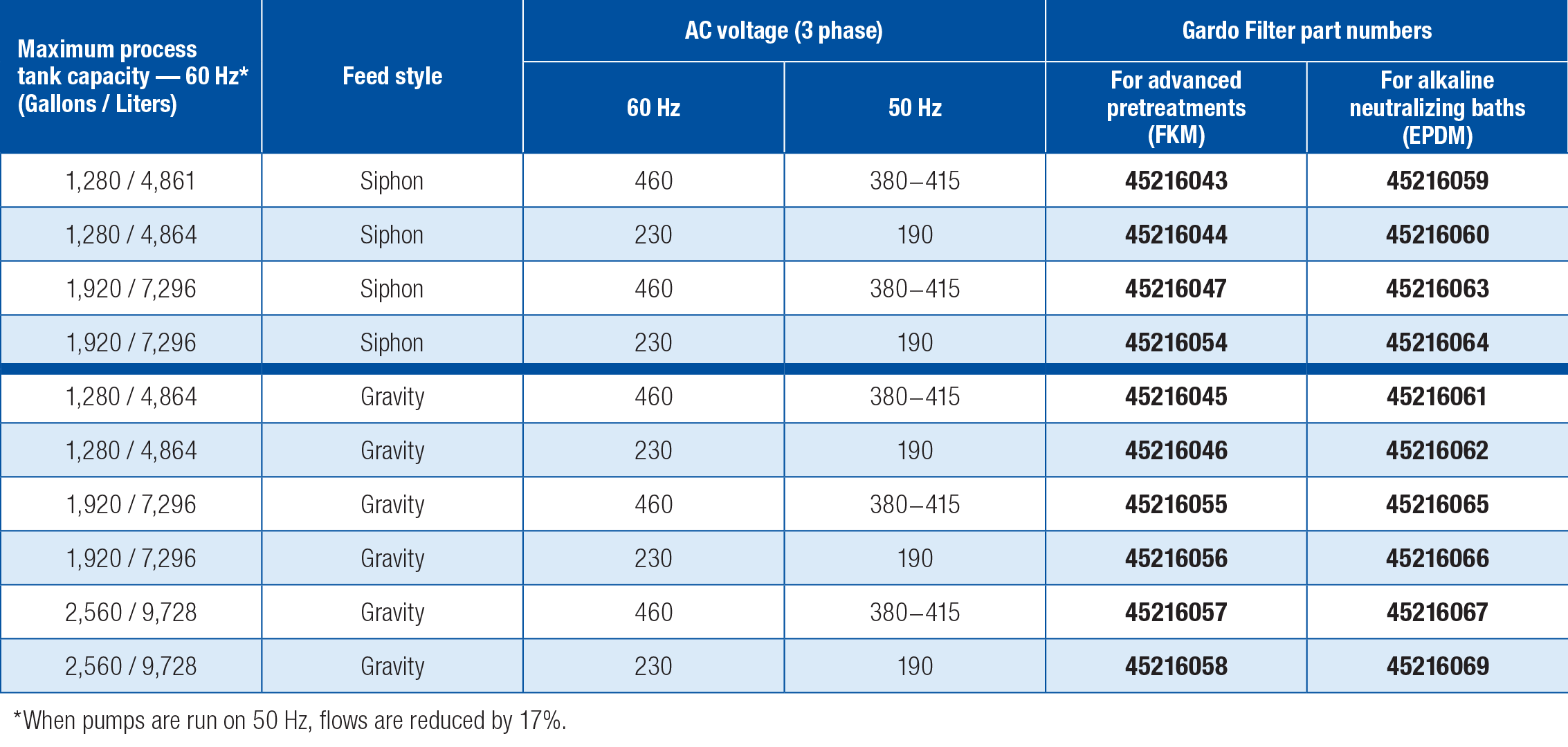

System specifications

Click table to view large.

System models available

Click table to view large.

Easy to maintain