Page 28 - BASF-CHEMETALL Metalworking Collateral (NA)

P. 28

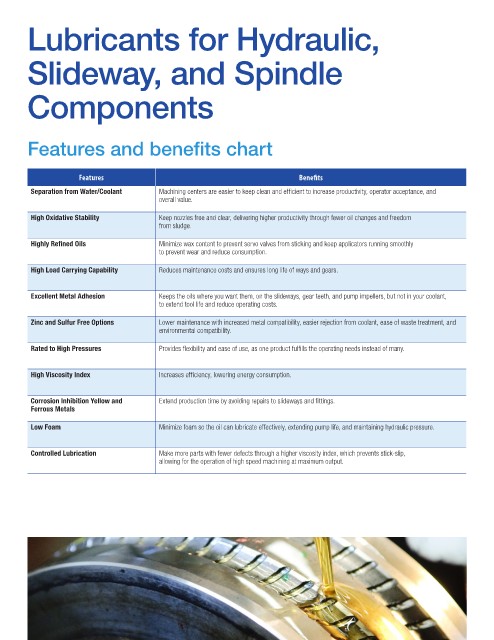

Lubricants for Hydraulic,

Slideway, and Spindle

Components

Features and benefits chart

Features Benefits

Separation from Water/Coolant Machining centers are easier to keep clean and efficient to increase productivity, operator acceptance, and

overall value.

High Oxidative Stability Keep nozzles free and clear, delivering higher productivity through fewer oil changes and freedom

from sludge.

Highly Refined Oils Minimize wax content to prevent servo valves from sticking and keep applicators running smoothly

to prevent wear and reduce consumption.

High Load Carrying Capability Reduces maintenance costs and ensures long life of ways and gears.

Excellent Metal Adhesion Keeps the oils where you want them, on the slideways, gear teeth, and pump impellers, but not in your coolant,

to extend tool life and reduce operating costs.

Zinc and Sulfur Free Options Lower maintenance with increased metal compatibility, easier rejection from coolant, ease of waste treatment, and

environmental compatibility.

Rated to High Pressures Provides flexibility and ease of use, as one product fulfills the operating needs instead of many.

High Viscosity Index Increases efficiency, lowering energy consumption.

Corrosion Inhibition Yellow and Extend production time by avoiding repairs to slideways and fittings.

Ferrous Metals

Low Foam Minimize foam so the oil can lubricate effectively, extending pump life, and maintaining hydraulic pressure.

Controlled Lubrication Make more parts with fewer defects through a higher viscosity index, which prevents stick-slip,

allowing for the operation of high speed machining at maximum output.